PE foam machine manufacturer & Supplier & Exporter

Specialized in EPE machine 23 years

1. EPE foam machines of 16 kg /m³, that is the same thickness as the production of EPE in the same material, the Jinlida of the EPE foam machines produced far more than the volume length counterparts

2. On-site commissioning and installation, provide the training of customer’s technical staff, until customer complete master of the technology.

info@lzjinlida.comEPE foam machine Technical data

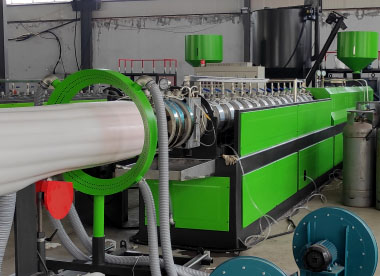

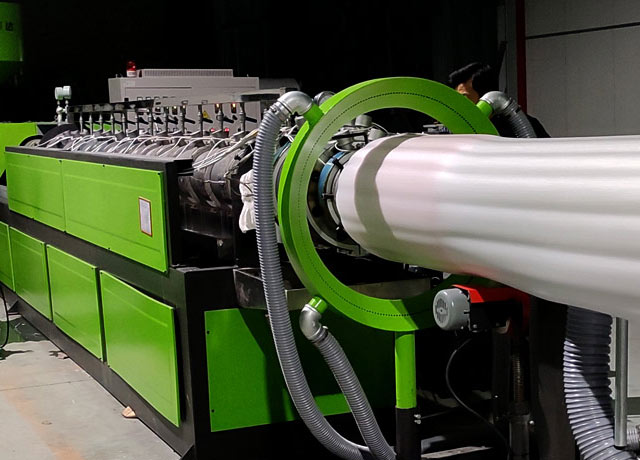

The equipment (EPE foam machine) is mainly used for the production of EPE sheet; tube, bar; profile, LDPE resin will melt mixed with butane gas, talcum, monoglyceride, extruder high pressure squeeze And die in the mold lip part of the foam, and then through the stereotypes cylinder to fix the sheet size, the final product by the take-up roll coiling.

| Model | Screw dia (mm) | width (mm) | Thickness(mm) | Total power (KW) | Output (kg/h) | Foaming times | Dimension(m) |

| EFP-75 | 75 | 850~1600 | 0.2-3 | 55 | 25-50 | 9-64 | 20*4*3 |

| EFP-90 | 90 | 850~2000 | 0.2-4 | 75 | 60-90 | 22*4*3 | |

| EFP-105 | 105 | 850~2000 | 0.3-6.5 | 95 | 80-120 | 25*4*3 | |

| EFP-120 | 120 | 850~2000 | 0.5-8 | 115 | 120-180 | 27*4*3 | |

| EFP-135 | 135 | 850~2000 | 1-10 | 150 | 170-220 | 35*4*3 | |

| EFP-150 | 150 | 850~3000 | 2-12 | 220 | 250-300 | 38*7*3 | |

| EFP-170 | 170 | 850~3000 | 2-15 | 320 | 100-450 | 40*7*3 | |

| EFP-180 | 180 | 850~3000 | 3-18 | 330 | 300-500 | 41*7*3 | |

| EFP-200 | 200 | 850~3000 | 3-20 | 400 | 350-650 | 42*7*3 | |

| EFP-220 | 220 | 850~3000 | 3-22 | 450 | 400-700 | 43*7*3 | |

| EFP-250 | 250 | 850~3000 | 3-25 | 500 | 450-800 | 46*7*3 | |

| EFP-280 | 280 | 850~3000 | 5-27 | 560 | 500-900 | 49*7*3 | |

| EFP-300 | 300 | 850~3000 | 5-30 | 600 | 550-1000 | 50*7*3 |

If you have question about EPE foam machine,please send Email:info@lzjinlida.com or add Wechat:51930951

In recent years, with the wide application of EPE foam sheet in vegetable greenhouses in Weifang, Shandong province, the width of customer processing of EPE is also required to reach 3 meters and 4 meters . The width of EPE foaming machine produced by Laizhou Jinlida Machinery can be up to 3 meters, 4 meters or even wider, we can customize special specifications of EPE foam machinery equipment according to customer requirements.

Explore Your EPE Foam Machine

LaiZhou Jinlida Machinery Co ., Ltd specialize in designing, developing and supplying a wide variety of technologically advanced machines that are used in packaging, construction and various other industries. Given below is a complete list of our offered machines:

EPE foam machinery six characteristics

Since it was founded in 2003, we only have made EPE foam machinery, and the EPE foaming machine is our flagship product. All other small equipments are used for its supporting purposes. We only have the EPE foam sheet machine do the better work to make it be NO.1 in the industry.

Email: info@lzjinlida.com

EPE foam sheet light weight and strong competitiveness

JinLida EPE foaming machine produces EPE foam sheet up to 14 kg/cubic

Feed section and Cooling water circulation

Cooling water circulation prevents temperature from rising, resulting in stickiness, agglomeration, and blockage of raw materials

Custom die head and moulds

Replacement of epe foam sheet extruder head mold and auxiliary machine can produce pearl cotton roll, pipe stick, U-shaped groove edge protection, etc. More please add wechat:51930951

Sizing drum and product thickness adjustment

The industry's unique thickness-cutting device without torsion is easy to operate.

Upwind and rewind use double in despondently turns with meter automatically.

The length of the rewinding sheet can be set. The A reel reaches the set length and automatically rotates 180° B. The reel starts to rewind the sheet, and the A-axis automatically stops.

High configuration and Strict requirements

The mechanical part of the material workmanship is very elegant, and each part and every detail are carefully checked to ensure long-term and efficient use of the equipment.

Why choose our EPE foam machine

The craftsman spirit of professional China manufacturer of EPE foaming machine since 2003

Focus on specialization

Since it was founded in 2003, it has been focusing on the production of first-class R&D and manufacturing teams for EPE foaming machinery and its ancillary equipment, as well as the first-line worker mastering 23 years of production and processing experience.

According to customers’ requests of feedback ,we improve the functional requirements of EPE foam machinery equipment in a timely manner, so that our plant has the functionality and practicality of the EPE equipment more in line with customer requirements and operating habits.

Configure high performance quality assurance

EPE foam extruder machine screw, power system, temperature control system, injection system, electrical control system using well-known brands at home and abroad, the operation of all links can be long-term high-intensity uninterrupted boot-up.

The failure rate is low and the service life is long. The mechanical part is very elegant in terms of materials and workmanship. Each part and every detail is carefully checked and the equipment can be used efficiently for a long period of time. And its life is 30-50% higher than other manufacturers' equipments.

Factory Test Verification and Flexible Payment

The process is "signing the contract" to the engineer, progress supervision, workshop director, work order under the electronic control department, engineer cad drawing, workshop production according to drawing, electric control department begins assembly of electric panel and related electronic control program, progress supervision Control progress, Equipment complete, Test machine (test machine process customer participation), Satisfaction test machine full payment, Arrange shipment"

Each device undergoes a rigorous testing procedure and factory customers participate in the test machine. Only after satisfaction is it paid for the full amount of money. This will enable customers to resolve their concerns.

Mature and Sophisticated after-sales service

It’s our duty to install and debug the products and train the customers for free until they learn how to use it.

We offer you the using technological consultation of professional EPE foam machine, perfect after-sales service team in order to help you solve problems quickly.

We offer technical support and solution in the shortest time after failure declaration anytime. Please call at tel: 8613686387253.Or wechat:51930951 or send me email:info@lzjinlida.com

Products are competitive.

High foaming rate and light weight have great competitive advantages. The density of 0.5mm thick sheet is 15 kg/m3 and even down to 14 kg/m3.

The products have uniform and fine cells, smooth and delicate surface, good elasticity, good physical properties and good sales.

Energy-saving and stable failure rate of equipment

Main motor adopts advanced frequency conversion technology and high-speed and low-variation mode to maximize the effect of frequency conversion and energy conservation

The failure rate is low and the service life is long. The mechanical part is very elegant in terms of materials and workmanship. Each part and every detail is carefully checked and the equipment can be used efficiently for a long period of time. And its life is 30-50% higher than other manufacturers' equipments.