Contact us

Wechat : 51930951

Email : info@lzjinlida.com

Tel: +86-13686387253

Fax: +86-0535-2626798

Add: Pinglidian industrial development zone, Laizhou City, Shandong Province

Wechat : 51930951

Email : info@lzjinlida.com

Tel: +86-13686387253

Fax: +86-0535-2626798

Add: Pinglidian industrial development zone, Laizhou City, Shandong Province

- In April 2003, Mr. Wang and Mr. Wang established Laizhou Chengxin Plastic Machinery Factory, specializing in EPE pearl cotton sheet extruder.

- In 2004, sales exceeded 4 million.

- In 2005, sales exceeded 6 million and the number of personnel increased to 20.

- When Laizhou Chengxin Machinery Factory was upgraded to a limited company in 2007, the integrity word could not be registered. The name changed from Laizhou Chengxin Machinery Factory to Laizhou Jinlida Machinery Co., Ltd., and at the same time, we began to search for a new factory site.

- After years of rapid development, in 2009, the original factory in the Laizhou Development Zone was no longer suitable for the company's sustainable development. After careful consideration, the company’s leaders decided to relocate the factory to the industrial park in Pinglidian Town, Laizhou.

- In 2010, sales exceeded 10 million. Foreign trade companies export products to Iran, Vietnam, India and other countries in the world.

- In 2015, sales exceeded 20 million.

- In 2016 ,the Ministry of Foreign Trade established.

Reviews for Our EPE foam machine

Jinlida Machinery's EPE foaming machine and laminating machine made me earn a lot of money.

-Nestrov/ Uzbekistan customers

Jin Lida foaming machine is simple and practical and the training master has serious attitude and great technology skills.

-Asad Khan/ Pakistan customers

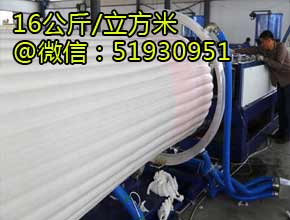

I was an regular customer of Jinlida Machinery. To begin with ,I bought the foaming machine of Jinlida Machinery because it was close to my factory. If there was a minor problem in the equipment or something wrong with the switch ,I can easily find them to solve it. The second is that as early as in the absence of reform and opening, the factory is the director of the state-owned enterprise technology, with deep qualifications, skills, honesty and trustworthiness. Afterwards, after using their foaming machine, I discovered that the products produced by Jinlida Machinery's Zhenzhumian foaming machine have high foaming magnification, light weight, and it has uniform and fine cells, smooth and delicate surface, good elasticity, good physical properties and good sales.

Their equipment performance quality and simple operation and practicality are very good. When I have any suggestion about them, they can also improve and perfect the machine according to my suggestion. I started from a small factory when I started my pearl cotton business and now I have nine pearl cotton plants in Shandong. Each year, I purchase more than 1 million equipments at Jinlida Machinery. In February of this year, I purchased 250 cotton pearls from Jinlida Machinery.:one foaming machine, three thickening machines for three meters, one thickening machine for four meters. I think the factory which has old brand of Jin Lida Machinery for 16 years can be trusted.

I was an regular customer of Jinlida Machinery. To begin with ,I bought the foaming machine of Jinlida Machinery because it was close to my factory. If there was a minor problem in the equipment or something wrong with the switch ,I can easily find them to solve it. The second is that as early as in the absence of reform and opening, the factory is the director of the state-owned enterprise technology, with deep qualifications, skills, honesty and trustworthiness. Afterwards, after using their foaming machine, I discovered that the products produced by Jinlida Machinery's Zhenzhumian foaming machine have high foaming magnification, light weight, and it has uniform and fine cells, smooth and delicate surface, good elasticity, good physical properties and good sales.

Their equipment performance quality and simple operation and practicality are very good. When I have any suggestion about them, they can also improve and perfect the machine according to my suggestion. I started from a small factory when I started my pearl cotton business and now I have nine pearl cotton plants in Shandong. Each year, I purchase more than 1 million equipments at Jinlida Machinery. In February of this year, I purchased 250 cotton pearls from Jinlida Machinery.:one foaming machine, three thickening machines for three meters, one thickening machine for four meters. I think the factory which has old brand of Jin Lida Machinery for 16 years can be trusted.