polythene foam air condition insulation pipe machine

The pipe diameter can be adjusted according to the production requirement, and principle of the polythene foam air condition insulation pipe machine(Air conditioner insulation pipe making machine)operation is simple and flexible.

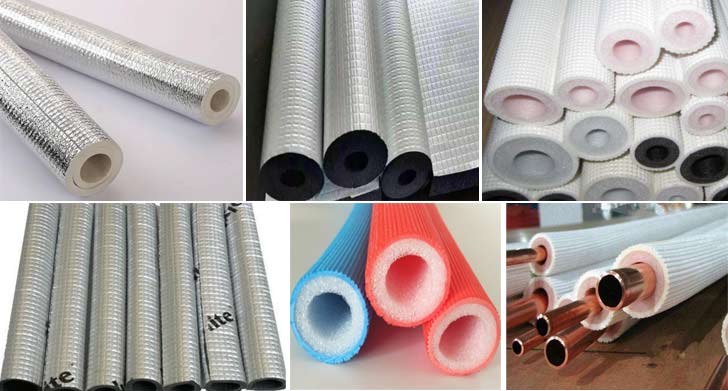

XPE tubes are widely used for the insulation of water pipes and air conditioner pipes. It has 3 layers, the inside is EPE foam pipe, the outside layer is XPE pipe laminated with a layer of PE or PVC film.

The pipe diameter can be made and cut according to the requirement.To make this kind of pipes, we need 4 sets of machines:

1.EPE foam pipe machine. (to make the inside epe foam pipe)

2.XPE Laminating machine. (to laminate XPE sheets with PE film)

3.Slitting machine. (to cut the laminated XPE+PE into strips and wind them into rolls)

4.Tube-rolling machine. (to roll the strips outside the surface of the epe pipe).

The working principle of the polythene foam air condition insulation pipe machine:

1. The XPE/PEF/EPE sheet will be cut according to the required tube diameter

2.The cut XPE/PEF/EPE sheet will be coated with aluminum film or color film

3. And then bonded together through heat melting to form tubular packaging products.

polythene foam air condition insulation pipe main application:

It is widely used in the fields of water pipe, air-conditioning heat-insulation pipe, floor heating insulation pipe, and children's playground protection.

The pipe diameter can be adjusted according to the production requirement, and the machine operation is simple and flexible.

1.Product Description:

This EPE foam tube/rod extrusion machine can produce EPE foam tube/pipe/rod/stick, which is a kind of new type foaming material and widely used as the air conditioner tube sheath, pool noodle, toy guardrail, etc due to its good foaming, elasticity and heat preservation character.

2.General characteristics:

-- polyethylene based products-inert material, highly resistant to chemicals

--environmental friendly products

--100% recyclable

--flexible low weight material, easy to slip and install

--low thermal conductivity

--compatible with all sealing materials

--fine round closed-cell cellular structure assures: negligent absorption and water permeability

--excellent impact and compression resistance even for low thickness

3.PE pipe extrusion line major design data

Resign applied :LDPE

Extruding capacity :approx 17-22kg/hr

The range of foam pipe diameter :15mm-45mm

Speed of the manufacture line:10-40m/min

4.Main Technical Parameters:

| Model | Screw Diameter(mm) | Tube Outer Diameter(mm) | Rod Diameter(mm) | Output(kg/h) | Installed Capacity | Dimension |

| EFP-75 | 75 | 10-60 | 6-38 | 20-40 | 55 | 16*1.3*1.7 |

| EFP-90 | 90 | 20-80 | 6-50 | 30-70 | 75 | 18*1.3*1.7 |

| EFP-105 | 105 | 20-100 | 10-80 | 40-100 | 95 | 25*1.3*1.7 |

| EFP-120 | 120 | 30-120 | 30-90 | 50-150 | 115 | 28*1.3*1.7 |

| EFP-135 | 135 | 40-140 | 40-100 | 70-180 | 150 | 30*1.3*1.7 |

| EFP-150 | 150 | 50-160 | 50-110 | 90-200 | 220 | 35*1.3*1.7 |

| EFP180 | 180 | 60-180 | 60-130 | 100-260 | 330 | 38*1.3*1.7 |

| EFP200 | 200 | 70-200 | 80-135 | 120-300 | 400 | 45*1.3*1.7 |

You may like

3d XPE Foam Wall Sticker Moulding Machine/XPE folding mat machine

XPE material cushioning - for the semi-rigid foam, after the impact of strong impact without loss of original performance, and more for precision instruments, semiconductor packaging and other fields, but also can use its easy formability, and for sports protection products And leisure products production areas.

epe foam sheet extrusion line

The production line for producing EPE foam sheet and the width of the pearl cotton can be adjusted.