foam insulation machine/line,aluminum foil backed foam insulation

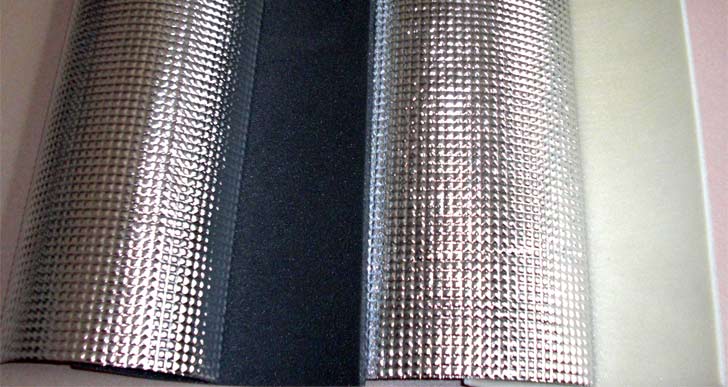

foam insulation sheets,aluminum foil backed foam insulation

EPE foam machine can make different foam sheet width and thickness according to customer requirement. Meanwhile, it can also make foam pipe, foam net, foam rod, foam profile and so on through changing mould and machine parts.

PE foam machine producing fine closed cell Polyethylene foam sheet, by our unique designed Screw and Barrel system, using Butane foaming agent, Talc powder or Talc master batch and Anti-shrinking agent (GMS for short-Surface Active Agent) by accumulated experience and advanced technology.

1.PE foam and related products are made from PE resin and it is expanded and formed into shapes by being heated and extruded. And it is easy to be decompounded and environment friendly.

2. Its key function is cushion protecting and warmth reserving.

3. Nowadays it is the most popularly used for modern batch production products, especially export packaging industry, including electronic industry (such as PC computer, laptop, electronic chips and parts, inverter, TV, air conditioner, refrigerator), furniture, glassware, garments, metal parts, etc.

4. Whoever aims at modern packaging and export, he has to use PE foam for the following reasons: Packaging with air bubble film, EPS and plastic film is forbidden in many countries.Paper packaging is so expensive.

5. PE foam products have quite a few varieties: Sheets for direct wrapping and to make bags; PE sheet may be coated with plastic film, craft paper and aluminum foil. It may be laminated (by electricity or LPG flame) into thick blocks. Then cut them to make different containers or frames. PE fruit net is direct for fruit and small matter's wrapping. If you add special molds, you may make different profiles for door hinges and furniture packing.

Model | Screw diametermm | Max width | Sheet thickness | Total power | Productivity | Foaming rate | L*W*H(m) |

EFP-75 | 75 | 1600 | 0.3-3 | 55 | 25-50 | 9-64

| 20*4*3 |

EFP-90 | 90 | 1600~2000 | 0.3-5 | 75 | 35-80 | 22*4*3 | |

EFP-105 | 105 | 1600~2500 | 0.3-6 | 95 | 50-120 | 25*4*3 | |

EFP-120 | 120 | 1600~3000 | 1-8 | 115 | 60-180 | 27*4*3 | |

EFP-135 | 135 | 1600~3000 | 1-10 | 150 | 70-220 | 35*4*3 | |

EFP-150 | 150 | 1600~3000 | 2-12 | 220 | 90-300 | 38*7*3 | |

EFP-170 | 170 | 1600~3000 | 2-14 | 320 | 100-450 | 40*7*3 | |

EFP-180 | 180 | 1600~3000 | 3-16 | 330 | 300-500 | 41*7*3 | |

EFP-200 | 200 | 1600~3000 | 3-25 | 400 | 350-650 | 42*7*3 | |

EFP-220 | 220 | 1600~3000 | 3-27 | 450 | 400-700 | 43*7*3 | |

EFP-250 | 250 | 1600~3000 | 3-30 | 500 | 450-800 | 46*7*3 |

PE foam sheet coating machine is to coat EPE sheet with film, aluminum foil or paper after heating, to increase the material's strength and other application.

PE Foam Sheet Coating Machine(EPE Foam Sheet Laminating Machine) is a deeply processing equipment of EPE foam sheet/film products, mainly used for the tectorial surface of EPE foam sheet/film.The material can be PE film,plated Aluminium foil, plactic-coated paper,plastic-coated fabric and so on.

Laminited foam sheet increases intensity, waterproof, and can be printed character, picture,improving the products grade,widely used for the packing of box lining,life vest,wooden floor underlayer.Car havelock,motor adumbral cushion,houdehold appliance.high-top Pottery and so on.

| Model | FM1400 | FM1700 | FM2200 |

| Product width (mm) | 1200 | 1500 | 2000 |

| Heating method | Electricity heating | Electricity heating | Electricity heating |

| Main power (kw) | 1.5 | 2.2 | 4 |

| Machine rated power | 10 | 15 | 35 |

| External dimension (m) | 4.5*1.8*1.2 | 4.5*2.2*1.2 | 4.5*2.3*.1.2 |

You may like

3d XPE Foam Wall Sticker Moulding Machine/XPE folding mat machine

XPE material cushioning - for the semi-rigid foam, after the impact of strong impact without loss of original performance, and more for precision instruments, semiconductor packaging and other fields, but also can use its easy formability, and for sports protection products And leisure products production areas.

epe foam sheet extrusion line

The production line for producing EPE foam sheet and the width of the pearl cotton can be adjusted.