Differences Between Thermal Oil Roller Laminators, Hot Air Laminators, and Extrusion Coating Machine

This is a highly specialized question involving three mainstream film lamination or coating processes. Their underlying principles differ, resulting in significant variations in application scenarios and final product performance.

I. Detailed Explanation of Working Principle and Process

1. Thermal Oil Roller Laminator

Core Principle: Hot-press lamination.

Process:

The substrate (e.g., paper, cardstock) and film (e.g., BOPP, PET) are guided onto a large heating steel roller internally filled with high-temperature thermal oil.

At the “hot press nip point” formed between the steel roller and pressure roller, heat and pressure are simultaneously applied to both substrates.

If the film is pre-coated with adhesive, heat activates the adhesive layer on its backing, melting it to bond with the substrate.

If the substrate is pre-coated with adhesive, heat activates the adhesive layer on the substrate to bond with the film.

The laminated material is then cooled and set.

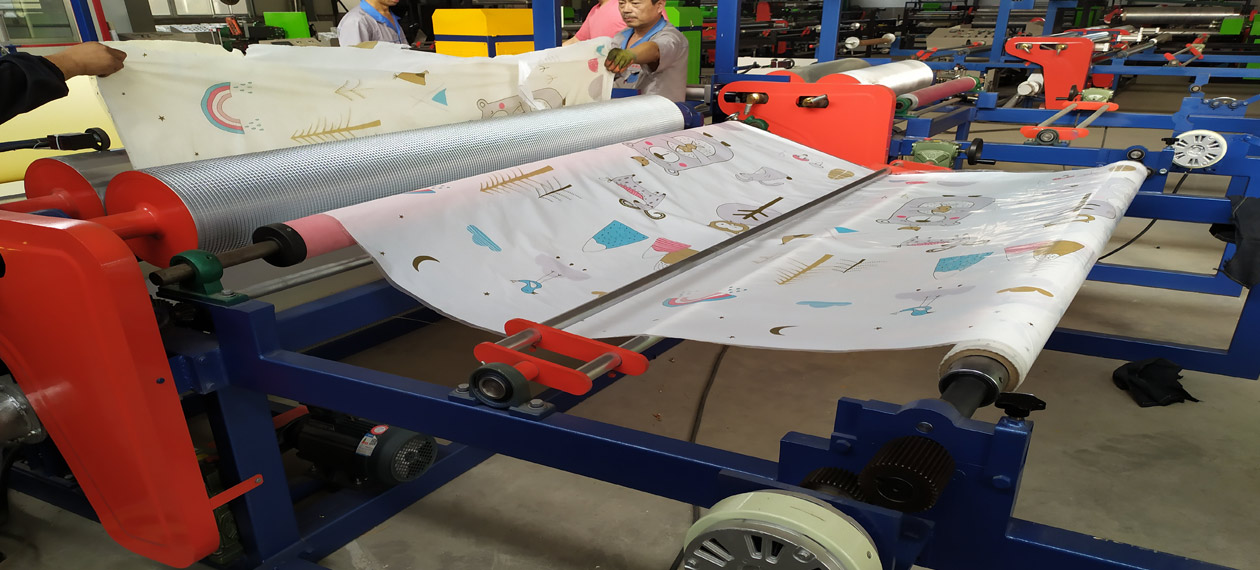

2. Hot Air Laminating Machine

Core Principle: Hot air bonding.

Process:

The substrate (typically metallized film, aluminum foil, woven fabric, or paper) must first have a PE film layer on its surface, applied beforehand via an extrusion coating machine.

The PE layer on the substrate surface and EPE foam are melted by hot air, then laminated together using rollers.

Key Feature: Throughout the process, materials never directly contact high-temperature metal rollers; heat is transferred solely via hot air.

3. Extrusion Coater / Extrusion Laminator

Core Principle: Melt Coating/Laminating.

Process:

Plastic raw materials (e.g., LDPE, PP pellets) are heated and melted in an extruder to form a uniform melt.

The melt flows through a wide T-die in a curtain-like pattern.

The melt curtain is directly coated onto the substrate surface (e.g., paper, non-woven fabric, aluminum foil, plastic film).

Immediately afterward, the melt and substrate pass through a nip point formed by a cooling steel roller and a pressure rubber roller. Here, they are pressed together, cooled, and cured, forming a uniform polymer coating on the substrate surface.

This can be a single layer or a multi-layer co-extruded composite.

II. Core Differences and Comparisons

| Characteristic Dimension | Thermal Oil Roller Laminating Machine | Hot Air Laminator | Extrusion Coating Machine |

|---|---|---|---|

| Bonding medium | Pre-applied hot melt adhesive layer (on the film or on the substrate) | PE layer | The plastic melt itself (e.g., LDPE) |

| Calorie Sources | High-Temperature Steel Rollers (Thermal Oil Heating) | Recirculating Hot Air | Heat from the plastic melt + cooling roll |

| Contact with heat sources | Direct contact with high-temperature steel rollers | <Non-contact (Hot Air Heating) | The melt contacts the substrate, and the substrate contacts the cooling roll. |

| Product Appearance | Exceptionally high gloss, mirror-like finish, perfectly smooth. | Matte/Non-glossy finish, with a natural texture and pronounced paper feel. | Depending on the substrate and surface treatment of the laminate, it can be glossy or matte. |

| Product Hand Feel and Physical Properties | Stiff, but due to high temperature and pressure, the paper may become brittle. | Soft and smooth to the touch, while maintaining the paper's original resilience. | Imparts new properties to the substrate (waterproofing, heat-sealing, etc.), with the feel determined by the coating thickness. |

| Peel Strength | Extremely high, with strong adhesion. | Medium to high, extremely sturdy, especially suitable for thick paper. | Exceptionally high, with the melt penetrating and bonding with the substrate to form a near-monolithic structure. |

| Primary Applications | High-end printed laminating: For applications requiring high gloss and protection, such as book covers, posters, gift boxes, and luxury packaging. | Thicker film | Functional Packaging Material Manufacturing: Such as paper cup base paper (PE-coated), Tetra Pak base material for milk cartons, waterproof breathable membranes, and nonwoven composite materials for medical protective clothing. |

| Environmental Protection and Safety | Using solid pre-coated adhesive film, solvent-free, but with high energy consumption. | Solid adhesive powder is used, which is solvent-free and contains minimal VOCs, making it relatively environmentally friendly. | Uses plastic pellets, solvent-free, but involves plastic processing. |

| Cost Considerations | Equipment costs are relatively high, and the cost of pre-coated adhesive film is relatively high. | Equipment costs are relatively high, while rubber powder costs are moderately high. | Equipment investment is significant (extruders are expensive), but raw material (pellets) costs are low. |

III. How to Choose? Scenario Summary

For premium visual displays requiring ultimate gloss, mirror-like finish, and maximum peel strength -> Select thermal oil roller laminator.

For printed materials requiring frequent handling, seeking natural matte texture, soft handfeel, and excellent fold resistance -> Select extrusion laminator.

When the goal is not surface beautification but imparting new functionalities to the substrate (e.g., waterproofing, oil resistance, heat sealability, enhanced barrier properties) for producing industrial or food packaging composites** -> Choose an extrusion laminator.

A simple analogy:

Thermal oil lamination is like ironing a sticker with an electric iron—flat and glossy.

Hot air laminating is like melting double-sided tape with a hair dryer, resulting in a flexible bond.

Extrusion coating is like pouring melted chocolate over a cake, forming an entirely new, functional coating layer.

Why Choose Us

China manufacturer of EPE foam machinery since 2003.EPE foam machine not only have covered all over China, but also have exported to more than 70 countries

Would you like to take a closer look at our offer?

You May Like:

We are making Differences Between Thermal Oil Roller Laminators, Hot Air Laminators, and Extrusion Coating Machine factory, manufacturer & supplier & exporter.We specialize in making EPE foam machine for over 20+ years