EPE Foam Insulation vs. Air Bubble(Bubble Wrap) Insulation: Differences and Advantages/Disadvantages

Expanded polyethylene (EPE) foam and air bubble flim are both common packaging and insulation materials, but they differ significantly in structure, operating principles, and suitable applications.

Detailed Comparison and Analysis of Advantages and Disadvantages Between EPE Foam (EPE) and Air Bubble Flim (Bubble Wrap)

I. Fundamental Differences in Structure and Materials

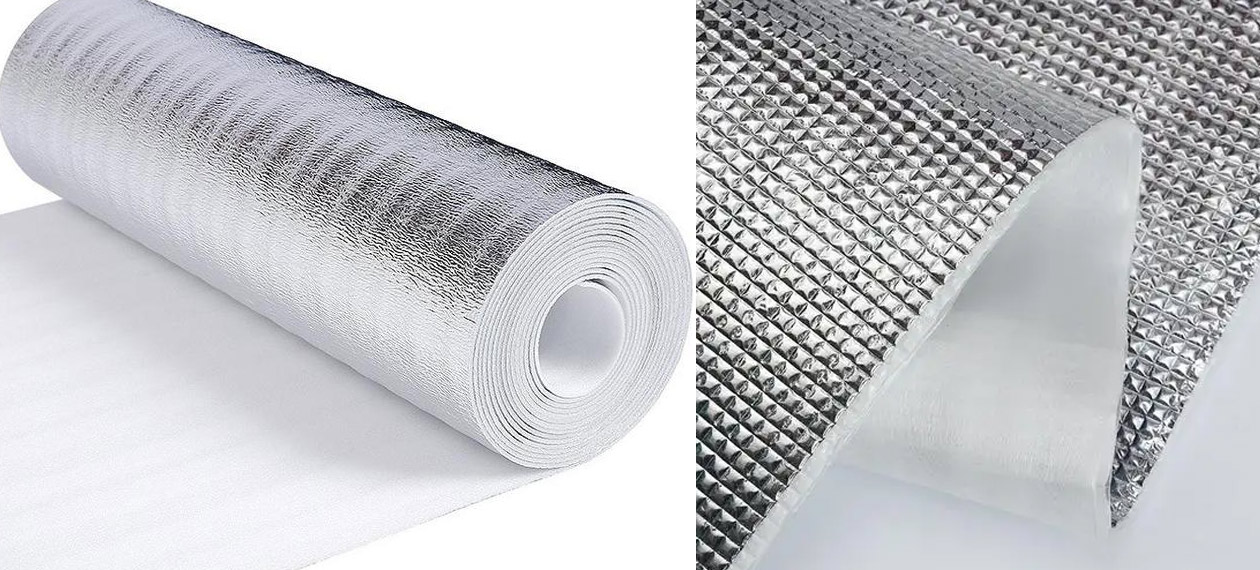

EPE Foam (EPE):

Material: A continuous cellular material formed by physically foaming low-density polyethylene (LDPE). Each tiny bubble is an independent or semi-independent closed cell.

Form: Resembles a sponge but consists of closed-cell foam, offering a more resilient texture.

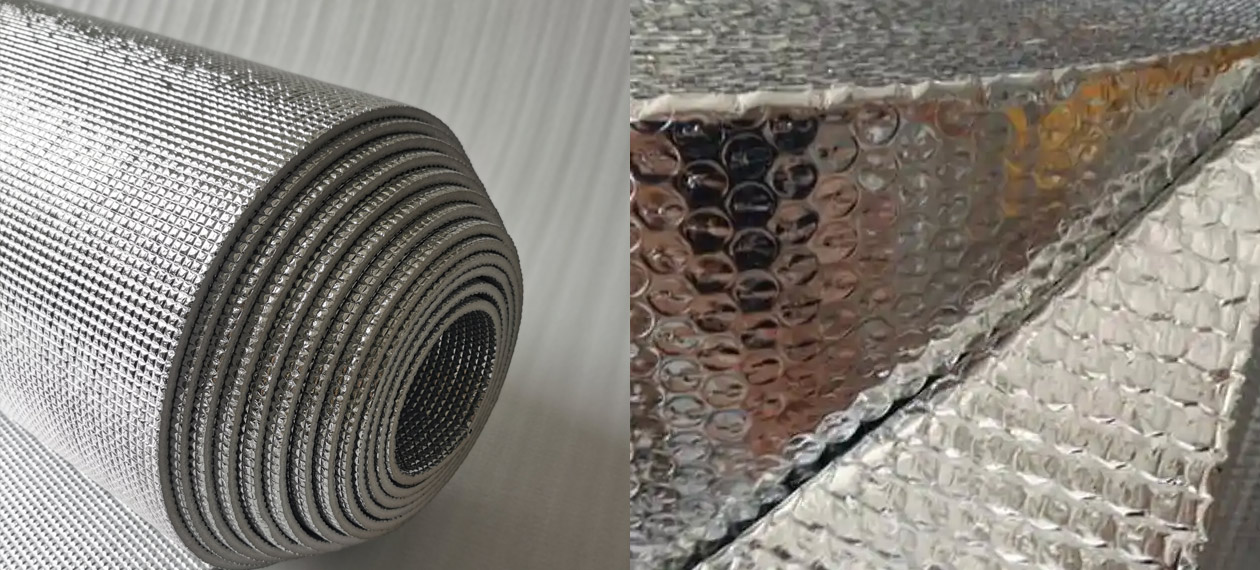

Air Bubble(Bubble Wrap):

Material: Two layers of polyethylene (PE) film, with one layer encapsulating air during processing to form sealed, independent air columns.

Form: Film + air sacs, extremely soft.

II. Differences in Thermal Insulation Principles

EPE Foam (Expanded Polyethylene):

Thermal insulation primarily stems from the foam material itself. The closed-cell structure traps air within tiny plastic cells. Both plastic and stationary air are poor heat conductors, creating an insulating layer.

Thermal performance remains stable and is not easily affected by external pressure or punctures.

Air Bubble(Bubble Wrap):

Thermal insulation relies almost entirely on the stationary air sealed within the air columns. Air is an excellent insulator, and these air pockets form an effective thermal barrier.

Thermal performance is fragile; once bubbles are flattened or punctured, insulation effectiveness declines sharply.

III. EPE Foam Insulation vs. Air Bubble(Bubble Wrap) Insulation In-Depth Comparison of Advantages and Disadvantages

| Characteristic Dimension | EPE Foam (EPE) | Bubble wrap (Air Bubble Film) |

|---|---|---|

| Thermal insulation properties | Advantages: Low thermal conductivity (typically 0.035–0.045 W/m·K), long-lasting and stable insulation performance, and minimal susceptibility to environmental factors. | Moderate (but prone to failure). Initial thermal insulation is effective (due to air), but once bubbles rupture or collapse under prolonged pressure, the effectiveness rapidly diminishes. |

| Moisture Resistance | Excellent. The closed-cell structure is impermeable and non-absorbent, acting as a moisture barrier in itself. | Poor. Merely a thin film, not moisture-proof. Water vapor can permeate it, and if damaged, water will seep through directly. |

| Buffer Protection | Excellent. Its resilient and elastic texture absorbs and disperses impact energy through self-deformation, offering superior impact resistance and making it ideal for protecting heavy objects and precision instruments. | Excellent (for lightweight items). Provides cushioning through compression deformation of air cushions, offering outstanding shock absorption and scratch protection, particularly suitable for products with easily damaged surfaces. |

| Strength and Durability | High. Strong tensile and tear resistance, puncture-resistant, and reusable multiple times. | Low. The film material is prone to puncture by sharp objects. Once damaged, the performance of the entire roll or sheet is significantly compromised. |

| Weight and Cost | Heavier, requiring more material per unit volume. Higher cost. | Ultra-lightweight. Extremely low cost, making it the preferred choice for budget packaging. |

| Processing and Environmental Protection | Can be easily laminated, bonded, cut, and formed into specific shapes. Can be recycled and regranulated, though the process is more complex than for film. | Simple to process but difficult to form. While also made of PE material, it is recyclable, but recycling centers accept fewer film-type materials. |

| Appearance and Feel | Opaque, with a substantial feel and a certain degree of stiffness. | Transparent or translucent, soft to the touch, rustling. |

IV. How to Choose Between EPE Foam and Bubble Wrap? Application Scenario Guide

Choose EPE foam when you need:

True thermal insulation: For cold chain logistics boxes, insulated bag liners, pipe insulation, temporary insulation panels, etc. Requires long-lasting, stable performance.

Heavy-duty or precision product cushioning: For appliances, electronics, instruments, furniture edge protection, etc. Requires material with sufficient strength and impact resistance.

Protection with moisture resistance: For storing humidity-sensitive items.

Custom molding: For pre-formed liners, trays, brackets, etc.

Choose bubble wrap when you need:

Filling, shock absorption, and surface scratch protection for lightweight items: Such as packaging small e-commerce goods, filling box voids, protecting glass/mirrors, craft packaging, etc.

Temporary, short-term thermal insulation: e.g., wrapping pipes to prevent freezing (requires multiple layers without damage), or applying to windows for minimal insulation.

Ultimate cost control: For routine packaging where unit cost is highly sensitive.

Visibility of contents: Transparent bubble wrap allows product display while providing protection.

Summary

EPE Foam is a “performance-oriented contender”: inherently a premium insulating and cushioning material, it is sturdy, moisture-resistant, and long-lasting, suitable for demanding applications—though at a higher price point.

Bubble wrap(Air Bubble) is the “air-utilizing champion”: it cleverly employs air for cushioning and temporary insulation. Extremely lightweight and inexpensive, it is fragile, non-moisture-proof, and prone to losing effectiveness, making it the king of economical, general-purpose packaging.

Simple decision-making mantra:

For long-term insulation, heavy-duty protection, or moisture resistance, choose EPE Foam.

For short-term cushioning, light-item scratch protection, or cost control, choose bubble wrap(Air Bubble).

Why Choose Us

China manufacturer of EPE foam machinery since 2003.EPE foam machine not only have covered all over China, but also have exported to more than 70 countries

Would you like to take a closer look at our offer?

You May Like:

We are making EPE Foam Insulation vs. Air Bubble(Bubble Wrap) Insulation: Differences and Advantages/Disadvantages factory, manufacturer & supplier & exporter.We specialize in making EPE foam machine for over 20+ years