Maintenance Guidelines for EPE Foam Machines

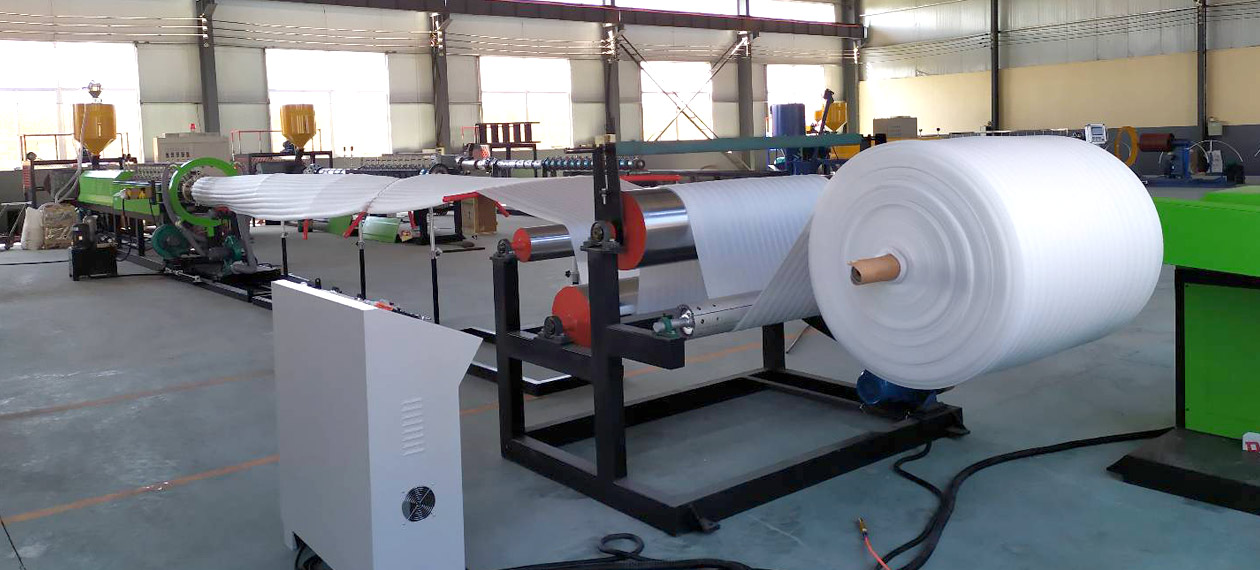

The EPE foam machine serves as the “heart” of the entire EPE production line, with its operational status directly determining product quality, production efficiency, and costs. Its maintenance is of paramount importance, necessitating the establishment of a scientific and rigorous preventive maintenance plan.

The following outlines a systematic set of maintenance considerations for EPE foam machines, covering daily, periodic, and critical component upkeep.

I. Core Maintenance Principles

Prevention First: Never wait for components to fail before repairing them; conduct scheduled preventive maintenance.

Documentation is Key: Establish a detailed Equipment Maintenance Record Form, documenting each maintenance task, parameters, replaced parts, and identified issues.

Professional Operation: Maintenance and repairs must be performed by trained professionals, especially for high-pressure, high-temperature, electrical, and precision components.

Genuine Parts: For critical components (e.g., screws, bearings, seals), use manufacturer-recommended original parts or high-quality equivalents with equivalent specifications whenever possible.

II. Daily/Per-Shift Maintenance of EPE Foam Machine (Operator's Responsibility)

This is the most fundamental and critical step, designed to promptly identify abnormalities.

1. Cleaning:

After shutdown, promptly clean raw material particles, oil stains, and foam scraps from the machine surface and surrounding area.

Keep control cabinet vents clean to prevent dust ingress.

2. Lubrication Inspection:

Check the oil level in the automatic lubrication system reservoir and inspect pipelines for leaks.

Apply specified grease to manual lubrication points (if present) according to regulations.

3. Key Parameter Inspection:

Observe whether heating temperatures across all sections remain within set ranges and are stable.

Check for abnormal fluctuations in main unit current and pressures (melt pressure, hydraulic pressure).

Listen for unusual operational sounds (e.g., friction, impact, abnormal noises).

4. Leak Inspection:

Check for leaks in the hydraulic system, lubrication system, and cooling water system.

Inspect foaming agent (butane, propane, etc.) pipelines and valves for odors or suspected leaks (strictly prohibit open flames; use a leak detector).

5. Drive System Inspection:

Verify smooth operation of motors and gearboxes, checking for abnormal vibration or overheating.

III. Weekly/Monthly Routine Maintenance of EPE Foam Machines (Performed by Maintenance Technicians)

1. Electrical System:

Check tightness of all electrical terminals to prevent overheating due to loose connections.

Clean dust from inside control cabinet (perform after powering off).

Inspect connections and operational status of heating coils and thermocouples.

2. Transmission System:

Check oil level and quality in gear reducer; replace gear oil regularly per manual specifications.

Check coupling alignment and elastomer wear.

Inspect tension of all drive belts or chains; adjust or replace as necessary.

3. Hydraulic System:

Check hydraulic oil level and condition (color, viscosity, presence of contaminants). Replace hydraulic oil and filter according to schedule (typically every 2000-4000 hours).

Clean fins of hydraulic oil cooler.

4. Cooling System:

Inspect the cooling tower and water tank, removing any debris.

Check the water pump's operational status, ensuring the water circuit is unobstructed with no blockages or leaks.

Verify that the cooling water temperature remains within the specified range.

IV. Quarterly/Annual Major Maintenance (Performed by Professional Team)

This is a thorough inspection and repair of the EPE foam machine.

Core Components—Extruder Screw and Barrel:

Annual overhaul is mandatory. After shutdown, remove the screw while hot for thorough cleaning and inspection.

Screw Inspection: Measure wear at critical points (diameter, flute width), check for scratches and corrosion. Wear exceeding tolerances requires repair or replacement.

Barrel Inspection: Assess inner wall wear and measure bore diameter. The screw-barrel clearance directly impacts extrusion pressure and foam quality; excessive wear must be addressed.

Cleaning: Thoroughly remove carbon deposits and residues from the screw and barrel using specialized screw cleaning compounds or physical methods.

Sealing System:

Inspect and replace screw seal rings (anti-leak rings), flange gaskets, various oil seals, etc. This is critical for preventing melt leakage, pressure loss, and contamination.

Heating and Temperature Control System:

Calibrate the accuracy of thermocouples and temperature controllers in all heating zones.

Inspect heating element resistance and insulation; replace aged or damaged heating elements.

Safety System:

Comprehensive Testing: All safety devices—emergency stop buttons, safety door switches, over-temperature/over-pressure alarms, gas leak alarms—must be 100% functional.

Calibrate pressure sensors and safety valves.

Foaming Agent Injection System (Critical Priority):

Inspect plungers and seals of the high-pressure injection pump.

Test all piping, valves, and fittings for leak-tightness and pressure resistance. Absolutely no leaks are permitted in butane/propane systems.

Clean or replace check valves to ensure their responsiveness and reliability, preventing melt backflow.

V. Specific Precautions for Key Components of EPE Foam Machines

Die Head and Die Mouth: Regularly (e.g., per shift or daily) clean material buildup from the lip using copper or specialized tools to prevent scratching precision surfaces. Before extended shutdowns, thoroughly flush with low-melt-index cleaning material.

EPE Foam Machine Filter Screen and Screen Changer: Replace the filter screen promptly when pressure increases. Inspect the hydraulic screen changer for proper sealing and smooth operation.

Bearings: Pay particular attention to thrust bearings and main machine bearings. Monitor operational sounds and temperatures, replacing them periodically according to their service life.

VI. Maintenance for Shutdown and Startup of EPE Foam Machines

For Extended Shutdowns (e.g., Spring Festival):

In cold climates, drain residual water from the gear reducer and circulation pipes to prevent freezing damage.

Shut off all power, air, and water supplies.

Seal oil lines in hydraulic and lubrication systems to prevent air ingress.

Apply rust-preventive oil to critical metal surfaces like screws and guide rails.

Before Startup:

Conduct a comprehensive inspection of all systems and perform a test run to verify motor rotation direction.

Initiate low-speed idle operation. Allow sufficient time for preheating and temperature rise (typically 2-4 hours) to ensure uniform temperature attainment across all sections.

Begin with a “run-in” using standard raw materials like LDPE. Once output becomes stable and uniform, gradually introduce the foaming agent.

Summary: The core of maintenance lies in “People, Records, and Planning.”

People: Train a professional team for operation and maintenance.

Records: Detailed data forms the foundation of predictive maintenance.

Planning: Develop and strictly implement the Tiered Maintenance Schedule (daily, weekly, monthly, yearly).

Implementing this epe foam machine maintenance system ensures maximum operational stability, extended lifespan, reduced energy consumption, and consistent product quality—representing the most cost-effective investment in the long term. We recommend developing customized maintenance protocols for your facility based on the manufacturer's official manual and the key points outlined above.

Why Choose Us

China manufacturer of EPE foam machinery since 2003.EPE foam machine not only have covered all over China, but also have exported to more than 70 countries

Would you like to take a closer look at our offer?

You May Like:

We are making Maintenance Guidelines for EPE Foam Machines factory, manufacturer & supplier & exporter.We specialize in making EPE foam machine for over 20+ years