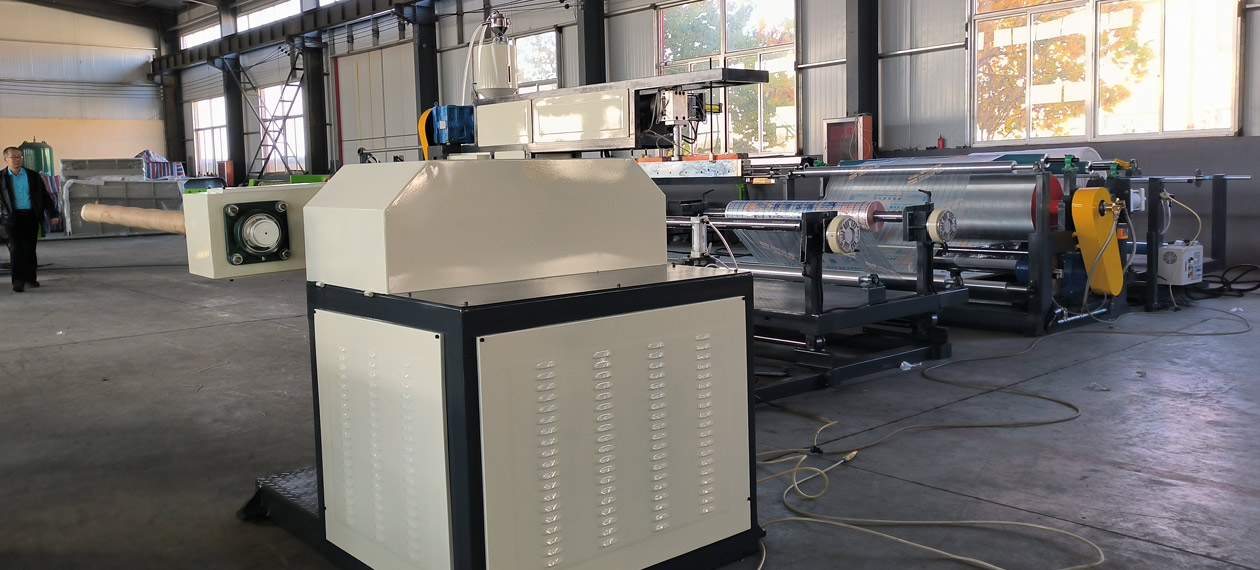

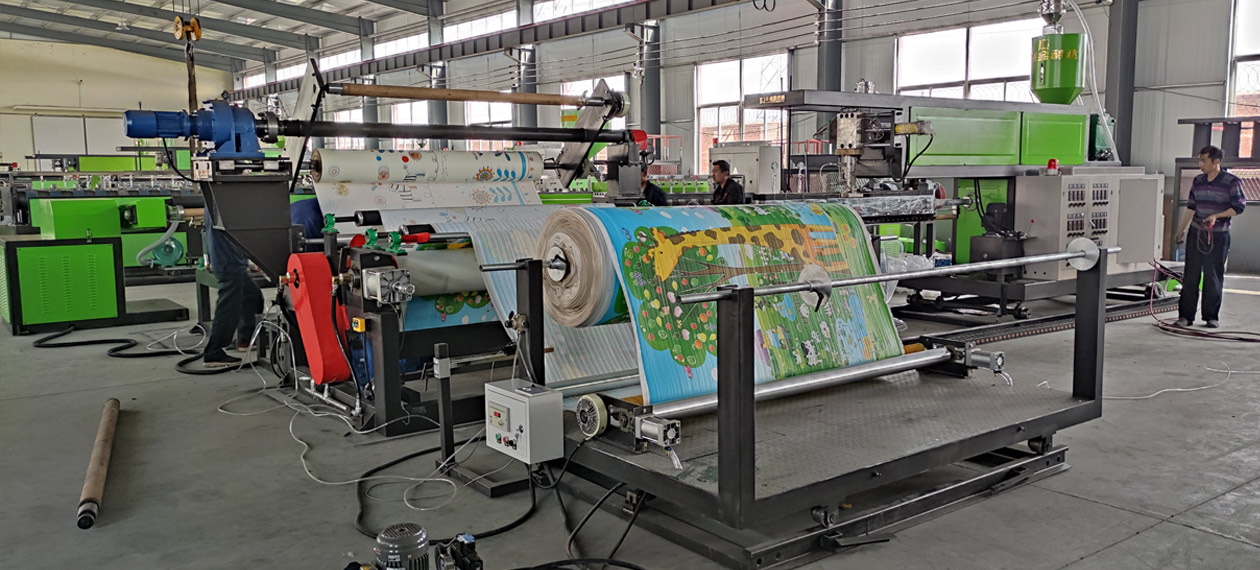

Daily Maintenance Guidelines For Coating Extruders(Extrusion Laminating Machine)

The coating extruder(Extrusion Laminating Machine) serves as the core power source and “heart” of the extrusion laminating production line. Its maintenance directly determines coating uniformity, coating quality, production continuity, and equipment lifespan. Compared to the entire coating line, maintenance of the extruder section demands greater expertise and precision.

The following outlines key maintenance considerations for coating extruders, categorized into daily/per-shift, periodic, and critical warnings.

Daily Maintenance Guidelines for Coating Extruders(Extrusion Laminating Machine)

I. Core Maintenance Principles for Coating Extruders(Extrusion Laminating Machine)

Temperature First: As thermal processing equipment, all extruder operations must revolve around temperature control. Never start the screw before temperatures reach specifications. After reaching setpoint temperatures, maintain the temperature for an additional half hour before commencing operation.

Cleanliness is Paramount: Plastic melt is extremely sensitive to contamination. Any carbonized particles, impurities, or cross-contamination of different raw materials will cause critical defects in the coating, such as crystalline spots, streaks, or pinholes.

Preventive Maintenance: Conduct maintenance based on trends in operating hours and critical parameters (e.g., current, pressure), rather than waiting for failures to occur.

II. Daily/Shift Maintenance (Operator Responsibility)

This forms the foundation for ensuring smooth production operations each day.

1. Pre-Startup Inspection for Coating Machine(Extrusion Laminating Machine):

Confirm Cleanliness: Inspect the hopper for cleanliness, checking for foreign objects, moisture, or residual material of different colors.

Check Lubrication: Verify the oil level/sight glass in the main gearbox and the oil tank level in the automatic central lubrication system are normal.

Cooling Check: Verify barrel cooling fans/water pumps are operational and water circuits are unobstructed.

Tightness Check: Perform a quick visual inspection for obvious looseness in flange connection bolts and motor anchor bolts.

2. Coating Machine(Extrusion Laminating Machine) Operational Monitoring (Critical Priority):

Temperature Monitoring: Closely observe deviations between actual and set temperatures across all heating zones (especially the die head). Fluctuations should be controlled within ±2°C. Immediately inspect heating elements or thermocouples upon detecting abnormal fluctuations or slow heating.

Parameter Monitoring: Record and observe main unit current and melt pressure. Abnormally high current may indicate poor plasticization, internal foreign objects, or insufficient lubrication; abnormal pressure fluctuations may indicate screen clogging or unstable raw material.

Auditory and Olfactory Checks: Listen for smooth, uniform operation of the gearbox and screw, noting any friction, impact, or abnormal noises. Check for the smell of burnt plastic from overheating decomposition.

Leak Inspection: Inspect connections such as the die flange and screen changer for melt leakage (commonly known as “melt leakage”).

III. Weekly/Monthly Routine Maintenance for Coating Machines (Responsibility: Maintenance Technician)

Electrical System:

Inspect all heating element connections for tightness and check for external damage or scorching. Measure resistance values to ensure they fall within normal ranges.

Verify thermocouple insertion depth and secure mounting to ensure accurate temperature readings.

Clean dust from control cabinet air ducts and filters.

Drive and Lubrication System:

Check gear reducer oil level and condition. Replace gear oil according to manual specifications (typically every 2000-4000 hours).

Inspect extruder barrel cooling fan blades for cleanliness and bearings for abnormal noise.

Replenish specified high-temperature grease in manually lubricated thrust bearings and other components.

Coating Machine (Extrusion Laminating Machine) Screw and Barrel (Indirect Inspection):

Indirectly assess screw and barrel wear by observing current stability and material output uniformity.

Consider potential screw wear if production decreases, melt temperature becomes uneven, or current fluctuations increase.

IV. Quarterly/Annual Deep Maintenance for Coating Machines (Performed by Professional Engineers)

Core Overhaul—Screw and Barrel Inspection and Maintenance:

Mandatory annually or based on production hours. After shutdown, extract the screw while hot.

Screw: Thoroughly clean all carbon deposits and residues. Measure screw outer diameter wear (especially metering and compression sections) using a micrometer. Inspect screw flute surfaces for scratches or corrosion. Severe wear (exceeding barrel clearance tolerance) requires repair or replacement.

Barrel: Inspect inner wall wear and measure inner diameter. The screw-barrel clearance is critical for plasticization, pressure, and output.

Cleaning: Thoroughly clean using specialized solvents or physical methods with copper tools.

Seal System Inspection and Replacement:

Inspect and replace die flange gaskets and manifold (perforated plate) seals.

Inspect the screw root seal ring (stop ring) to prevent material leakage backward.

Heating and Cooling System Calibration:

Verify the accuracy of thermocouples in each temperature zone.

Clean the barrel cooling air ducts and heat exchangers of the water-cooling system to ensure cooling efficiency.

Safety System Testing:

Test the effectiveness of safety devices including overload protection, over-temperature alarms, and mechanical safety rods.

V. Special Precautions for Coating Processes

Die head (T-die) maintenance is critical:

Daily: Before shutdown, thoroughly flush the die lip with cleaning material to prevent carbonization of residual material.

Weekly: Apply specialized die lip paste to maintain the surface and prevent oxidation.

Disassembly and Cleaning: Periodically (e.g., during material changes or production halts), disassemble the die head. Use a copper scraper or cork rod to clean all dead corners within the flow channels. Steel tools are strictly prohibited! Perform mirror polishing after cleaning.

Lifting: When disassembling or installing the die head, use balanced lifting equipment. Handle with care to prevent impact damage to the precision die lips.

Coating Machine(Extrusion Laminating Machine) Filter Screen and Screen Changer:

Replace the filter screen promptly when melt pressure increases (e.g., exceeding 30% of initial pressure).

Inspect the hydraulic screen changer for flat, clean sealing surfaces, smooth operation without jamming, and check hydraulic cylinders for internal leakage.

Raw Material Management is Paramount:

Maintain raw materials clean and dry. Moisture in materials causes bubbles in the coating.

When switching between different grades or colors of raw material, perform thorough transition cleaning using sufficient quantities of cleaning material.

Coating Machine(Extrusion Laminating Machine) Maintenance Procedure Summary Table

| Cycle | Maintenance Items | Key points |

|---|---|---|

| Each class | Startup inspection, operational monitoring, shutdown cleaning | Temperature monitoring and shutdown must be performed using cleaning fluid to purge the system. |

| Weekly | Heating/Cooling System Inspection, Lubrication Point Inspection, Visual Tightness Check | Prevent minor issues from escalating into major problems |

| monthly | Electrical Connection Inspection, Filter Replacement Schedule, Parameter Trend Analysis | Data-Driven Preventive Maintenance |

| Every year | Major overhaul of screw barrel, replacement of seals, and calibration of safety systems | Deep maintenance to restore equipment precision |

Final Core Recommendation:

Establish an Equipment Health Record for your coating extruder(Extrusion Laminating Machine), recording key parameters daily (section temperatures, current, pressure). When these parameters show trend-based changes—such as a gradual rise in current or increased temperature fluctuations—it signals the equipment is “calling for help,” prompting you to schedule maintenance. This predictive maintenance proves more economical and effective than any fixed-cycle servicing.

Why Choose Us

China manufacturer of EPE foam machinery since 2003.EPE foam machine not only have covered all over China, but also have exported to more than 70 countries

Would you like to take a closer look at our offer?

You May Like:

We are making Daily Maintenance Guidelines For Coating Extruders(Extrusion Laminating Machine) factory, manufacturer & supplier & exporter.We specialize in making EPE foam machine for over 20+ years