What machinery is required for producing EPE foam insulation?

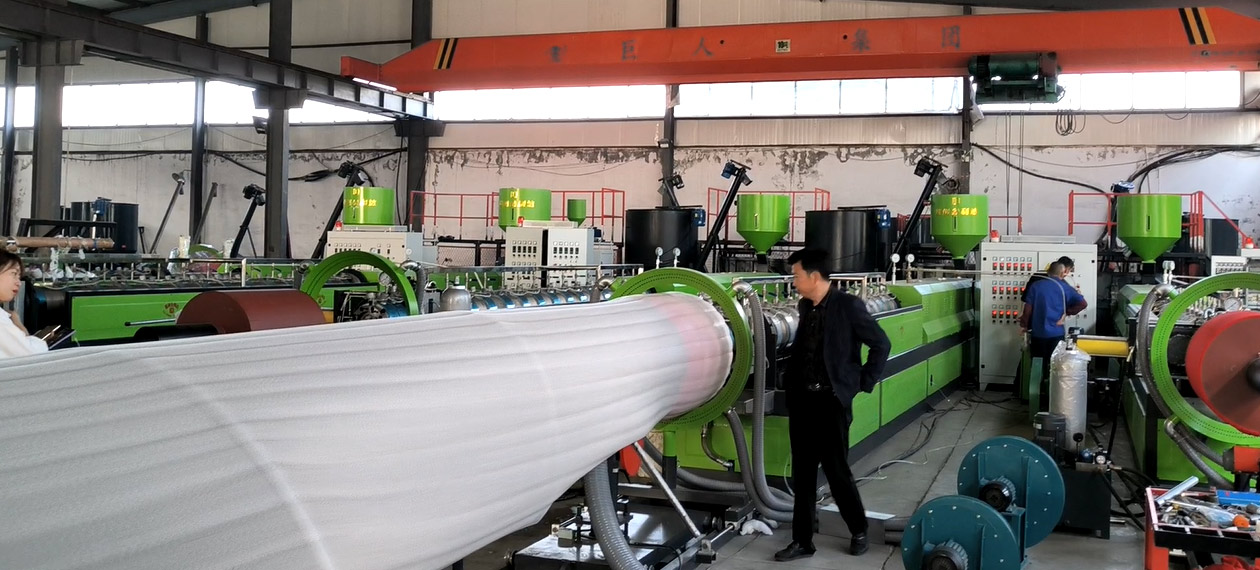

The core of producing EPE insulation cotton (sheets/rolls) is an “EPE physical foaming extrusion production line” and an EPE foam laminating machine.

A standard EPE insulation cotton (sheet/roll) production line primarily consists of the following five major units according to the process flow:

Unit 1: Automatic Feeding and Blending System

Function: Automated metering, mixing, and conveying of raw materials.

Raw Material Storage Tanks/Hoppers: Store LDPE (low-density polyethylene) as the primary material.

Precision Weighing Scale/System: Accurately measures and adds foaming agents (butane or CO₂), nucleating agents (talc powder), color masterbatch, flame retardants, and other additives.

High-Speed Mixer: Ensures uniform blending of all components.

Vacuum Feeder: Automatically and dust-free conveys the mixed material to the extruder's main hopper.

Second Unit: Extrusion Foaming System (Core Component)

Function: Completes plasticization, foaming agent injection, mixing/cooling, and extrusion molding.

Specialized Foaming Screw Extruder: Typically a high-length-to-diameter ratio single-screw or co-rotating twin-screw. Twin-screw offers superior mixing and more stable product quality. This is the “heart” of the production line.

Foaming Agent Injection System: High-pressure metering pumps, buffer tanks, etc., precisely inject liquid foaming agent into the melt under high pressure.

Melt Cooling System: Includes cooling screws and matching mold temperature controllers to precisely reduce melt temperature to the optimal foaming process temperature.

Ring Die: The high-temperature, high-pressure melt releases pressure here, expands and foams, forming a tubular blank. Die design determines the product's base thickness and roundness.

Third Unit: Forming, Traction, and Flattening System

Function: Inflates, cools, calibrates, slits, and flattens the foamed pipe blank into sheet material.

Forming Traction Frame: Features internal calibration sleeves and cooling air rings, with external traction belts that progressively expand, cool, and shape the pipe blank.

Defoaming Device (Stabilizer): Punctures internal bubbles within the tube blank, equalizes internal and external air pressure, and prevents product shrinkage or deformation.

Slitting Device: Longitudinally cuts the tubular blank.

Flattening Traction Machine: Gradually flattens the slit material to the required width while controlling the line speed of the production line.

Fourth Unit: Post-Processing and Finishing System (Optional based on product requirements)

Function: Performs functional processing on base sheets.

EPE Foam Laminator: Bonds aluminum foil film to EPE foam sheets.

Slitter/Cutter: Longitudinally slits wide material into strips or cross-cuts into sheets of specific lengths.

Key Production Techniques for EPE Foam Insulation

Density Control: The core metric for insulation cotton (typically 20-40 kg/m³). Precisely controlled by coordinating three factors: foaming agent injection volume, extrusion speed, and traction speed.

Cell Structure: Requires fine, uniform cells with high closed-cell content. This is determined by nucleating agents, process temperature/pressure curves, and cooling rates. Closed-cell structure ensures thermal insulation and moisture resistance.

Flame Retardancy: Typically required in construction, automotive, and other sectors. Achieved primarily by adding flame-retardant masterbatch (in-line process), necessitating selection of highly effective, environmentally friendly flame-retardant systems.

Product Specifications: Maximum production width (e.g., 1.2m, 1.6m, 2m) and thickness range (e.g., 3mm-30mm) must be determined during initial production line design.

EPE Foam Insulation Investment and Selection Recommendations:

| Considerations | Instructions and Recommendations |

|---|---|

| Product Positioning | Define your target market (construction, cold chain, automotive, piping?), determine product thickness, density, and whether it is flame-retardant/composite. |

| Production Capacity Budget | Production capacity (kg/h) determines the extruder model (screw diameter). For sufficient budgets, we recommend selecting a twin-screw system for greater stability and efficiency. |

| Supplier Selection | Critically important! It is essential to select a supplier with extensive successful experience in the EPE foam field. Require a “turnkey solution”, which includes: formulation guidance + equipment manufacturing + installation and commissioning + personnel training + process package. |

| Environmental Protection and Safety | Safety First! When using butane (flammable and explosive), equipment must feature explosion-proof certification, gas leak alarms, and powerful ventilation systems. CO₂ foaming is more environmentally friendly and safer, representing the trend, but it demands higher equipment and technical standards. |

| Subsequent processing | The production line can be equipped with reserved interfaces at the end, enabling future seamless connection to laminators, slitters, and other equipment to enhance scalability. |

Why Choose Us

China manufacturer of EPE foam machinery since 2003.EPE foam machine not only have covered all over China, but also have exported to more than 70 countries

Would you like to take a closer look at our offer?

You May Like:

We are making What machinery is required for producing EPE foam insulation? factory, manufacturer & supplier & exporter.We specialize in making EPE foam machine for over 20+ years