What is a EPE foam sheet machine?

1、 What is a EPE foam sheet machine?

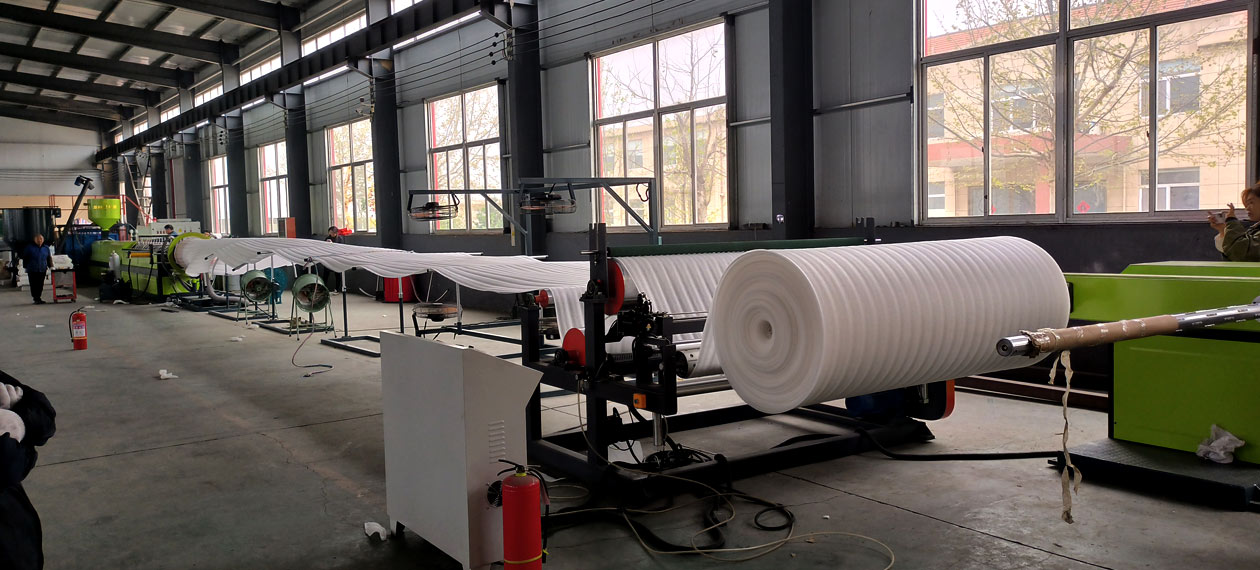

EPE foam sheet machine, fully known as"physical foaming polyethylene foam (EPE) production equipment", is a special mechanical equipment that continuously produces EPE foam (EPE) rolls or sheets by mixing low-density polyethylene (LDPE) particles with foaming agent (butane) and other raw materials through the physical foaming principle, heating, extrusion, cooling, shaping, traction, winding and other processes. It is the core production equipment of the EPE foam industry.

2、 Core working principle of EPE foam sheet machine: physical foaming

Plasticization mixing: LDPE particles are melted and plasticized under the shearing and heating of the EPE foam extruder screw, while being uniformly mixed with liquid butane foaming agent injected under high pressure.

Cooling homogenization: The mixed melt enters the cooling foaming machine screw, and the temperature is precisely reduced to the critical point suitable for foaming, while maintaining high pressure to prevent premature foaming.

High pressure extrusion: The homogenized melt is forced through a mold (die head) with a specific lip width.

Instantaneous pressure relief foaming: When high-pressure melt is extruded from the die to atmospheric pressure environment, the butane gas dissolved in the melt vaporizes and expands instantly, forming countless independent and fine closed bubbles in the polyethylene matrix, that is, foaming molding.

Forming traction: The foamed sheet material is gradually widened and thinned by a forming traction frame (commonly known as a "gantry frame"), and is cooled and shaped by cooling rollers and fans to form the final thickness of EPE foam roll.

3、 Main components of EPE foam sheet machine equipment

A complete EPE foam foam production line typically includes the following core units:

Extrusion system:

Main extruder: responsible for plasticizing and mixing raw materials. The core components are screws and barrels, usually single screws with a large aspect ratio and special mixing design.

Cooling screw: connected to the main extruder, with cooling water flowing inside, responsible for accurately reducing the melt temperature from the plasticizing temperature (about 180-220 ° C) to the foaming temperature (about 115-135 ° C).

Foaming agent injection system:

Butane pump, monoglyceride pump, etc.: Accurately measure and stably inject liquid butane and liquid monoglyceride into the melting section of the extruder.

Mold head system:

Molding die head: determines the initial width and thickness distribution of the product. The lip gap can be fine tuned.

Explosion proof device: Due to the flammability and explosiveness of butane, reliable explosion-proof discs or safety valves must be equipped at the mold head.

Auxiliary system:

Forming traction system (gantry):

This is the iconic component of the EPE foam machine. Composed of multiple rotating traction rollers, the EPE foam extruded by the foaming machine is pulled towards the winding by adjusting the speed of each roller to match the extrusion speed of the main machine.

Winder: Roll finished products into rolls of specified length.

Cutting machine: capable of online cutting into rolls or sheets of the desired width.

Edge material recycling system: After crushing the waste edges in production, they are mixed with new materials in proportion and reused to reduce costs.

Electrical control system: PLC (Programmable Logic Controller) and touch screen are the core, accurately controlling all parameters such as temperature, pressure, speed, and measurement.

4、 Production process flow

Raw material preparation → feeding → plasticization extrusion → butane injection mixing → cooling homogenization → mold extrusion → foaming expansion → traction stretching → cooling and shaping → edge cutting and winding (or slitting)

5、 Main classification of EPE foam sheet machine

Classified by product usage:

Ordinary roll machine: produces EPE foam rolls of conventional thickness for packaging.

Thin machine: specialized in producing ultra-thin EPE foam with a thickness of 0.3-1.0mm, used for padding or composite of clothing and handicrafts.

Thick type machine/profile machine: produces sheets with a thickness of over 30mm or profiles with specific cross-sections (such as angle steel and round bars).

Composite machine: online composite of EPE foam with film, aluminum foil and other materials to produce high-end composite packaging materials.

Classified by foaming agent type:

Butane foaming machine: the most mainstream, low cost, but requires strict explosion-proof.

CO ₂ foaming machine: more environmentally friendly and safe, but with higher equipment investment and operating costs, and slightly more difficult to control foaming ratio and product performance.

Classified by degree of automation:

Ordinary type: Basic control, relying more on worker experience.

Fully automatic type: adopting advanced PLC and temperature control module, the formula can be stored, the degree of automation is high, and the stability of the finished product is good.

6、 Key points and considerations for purchasing EPE foam sheet machine

Product planning: Clearly define the thickness range, width, and density (foaming ratio) of the main production products. Different specifications have different requirements for equipment configuration.

Production demand: Determine production capacity based on market forecasts (usually calculated in kilograms per hour or tons per day), determine extruder screw diameter (commonly available in sizes of 90, 120, 150, etc.), and set up production lines.

Raw materials and formulas: Whether to use recycled materials, whether to produce special EPE foam such as anti-static and flame-retardant, etc., will affect screw design and auxiliary equipment configuration.

Quality of key components of EPE foam sheet machine:

Screw barrel: material (whether nitrided or bimetallic), design (whether efficiently mixed).

Gearbox: The brand and load-bearing capacity determine the lifespan and stability of the equipment.

Electrical components: PLC, frequency converter, temperature control meter brands (such as Siemens, Mitsubishi, etc.).

Safety performance: Whether the explosion-proof system is complete and reliable (explosion-proof discs, gas detection, static elimination, ventilation), the workshop design must comply with safety regulations.

Energy consumption and cost-effectiveness: Compare the motor power and heating power of different manufacturers to evaluate long-term operating costs. Choose brands with stable quality and good after-sales service within the budget, rather than simply pursuing low prices.

Manufacturer Strength: Evaluate the manufacturer's technical expertise, successful cases, after-sales service network, and spare parts supply capabilities.

7、 Famous Brands and Markets (Domestic and International)

Foreign brands: In the early days, equipment technology from Germany, Italy, and South Korea was leading, but the prices were expensive. At present, the global market is basically dominated by Chinese made EPE foam sheet machines.

Domestic brands: After decades of development, they have become very mature and occupy the vast majority of the global market share. The main production areas are concentrated in Shandong, Guangdong and other places.

8、 Technological development trends

Green and environmentally friendly: promote the use of environmentally friendly foaming agents such as CO ₂; Increase the proportion of edge material recycling; Develop biodegradable polyethylene raw materials.

Intelligence and automation: Integrate MES (Manufacturing Execution System) to achieve remote monitoring, data tracing, intelligent scheduling, and fault diagnosis.

Efficient and energy-saving: Optimize screw design, adopt new energy-saving technologies such as electromagnetic heating, and reduce unit energy consumption.

Multifunctional: One machine with multiple uses, capable of quickly switching between producing products of different densities, thicknesses, colors, or online compounding.

Why Choose Us

China manufacturer of EPE foam machinery since 2003.EPE foam machine not only have covered all over China, but also have exported to more than 70 countries

Would you like to take a closer look at our offer?

You May Like:

We are making What is a EPE foam sheet machine? factory, manufacturer & supplier & exporter.We specialize in making EPE foam machine for over 20+ years